University Bioeconomy Partnerships

Connecting university research with real pathways into materials, processing, and regional bioindustrial development.

Universities shape the breakthroughs that become future industries. These partnerships give researchers the support, funding, and deployment channels needed to turn ideas into materials, equipment, and regional economic growth.

Research That Builds Regional Industries

Universities contribute the materials science, agronomy insight, engineering data, and testing standards that anchor new sectors. In the shift toward domestic hemp and bamboo supply chains, university involvement accelerates everything from fiber characterization to equipment design and field deployment.

Collaboration Opportunities

-

Materials Science & Engineering

Composite development, mechanical testing, surface treatments, coatings, structural applications.

-

Agronomy & Field Trials

Cultivar performance, soil health, carbon retention, irrigation efficiency, regenerative farming systems. -

Processing & Manufacturing Innovation

Decortication systems, pulping, milling, pyrolysis, densification, modular processing units.

-

Regional Pilot Projects

University-led deployment of fiber hubs, materials testing sites, and rural redevelopment projects.

A Funding Model Designed for Real Outcomes

The Research Accelerator uses a multi-backer structure similar to independent film financing. Projects receive support from the Bioeconomy Foundation, community crowdfunding, and matched grants when available. This creates stable research budgets that move quickly and benefit everyone involved.

Student Compensation

Students are paid full-time salaries to focus on research without the strain of outside jobs. Their attention stays on experiments, engineering tests, agronomy trials, and design challenges — not survival.

Student Royalties (10-Year Tail)

Students earn a small royalty for ten years if their project becomes part of commercial materials, processes, or systems. Their early contributions continue generating value long after graduation.

Faculty Royalties

Faculty members guiding research receive long-tail royalties when their expertise contributes to deployed industrial solutions.

Department & Administrative Fees

Universities receive structured compensation for lab oversight, facilities, equipment time, and project administration.

Community Micro-Backing

Parents, alumni, local businesses, and community members can contribute small amounts to student projects.

When a parent contributes $100, or a local hardware store puts in $250, they receive proportional royalty payments if the project enters industry. This invests the community directly in its future workforce and spreads long-term benefits across local families.

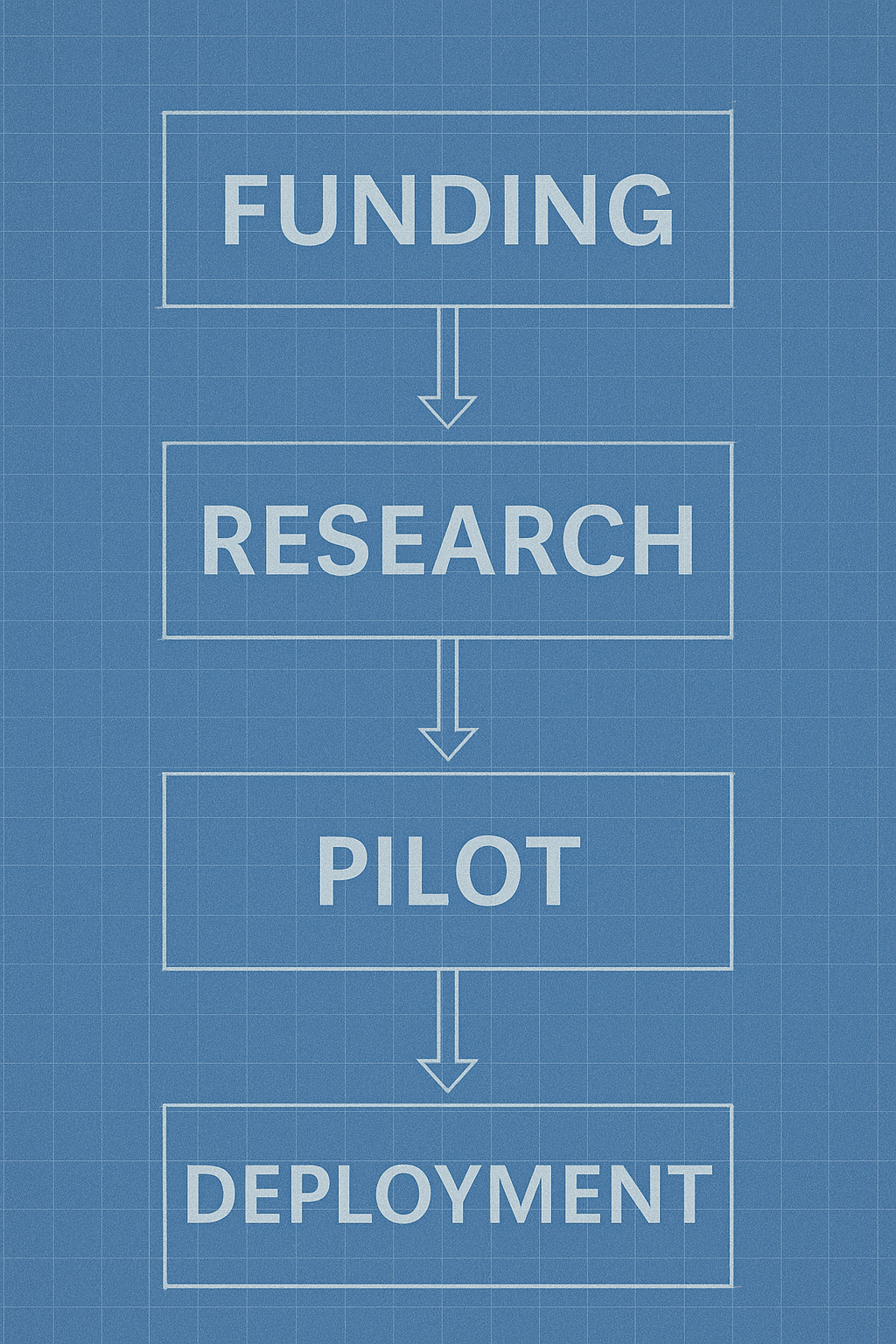

Deployment Path

Research flows into real-world use: processing hubs, equipment upgrades, pilot manufacturing runs, FEOC-compliant supply chains, and regional economic development.

A Clear Collaboration Framework

Partnerships follow a straightforward process:

Identify research needs and opportunities

Align capabilities with Foundation programs

Assemble funding from Foundation + community + grants

Conduct lab or field research

Transition findings into industrial pilots and regional deployment

Value for Partner Institutions

Universities gain:

reliable multi-source research funding

paid student researchers

faculty incentives through royalties

new interdisciplinary pathways

real-world deployment of research

visibility as leaders in fiber-based innovation

community-connected economic impact

Funding for all Foundation programs draws from the same coordinated model: Foundation grants, community micro-backing, matched grants when available, and industrial participation through American Fiber Group. DBX alignment ensures that successful work can enter procurement pathways, deployment pilots, and regional industrial systems.