Engineering Standards

The rules that make a real bioindustry possible.

Oil dominated because it had ASTM, ISO, and 70 years of foreign subsidy.

Hemp and bamboo get us and we’re not building a “green alternative.”

We’re building the replacement.

The Domestic Biofiber Index

Created by American Fiber Group

DBX is the engineering backbone of the new domestic fiber economy.

It defines how hemp and bamboo move from

field → hub → processor → manufacturer

with the consistency, traceability, and performance required for full industrial adoption.

THE 5 DBX CORE PILLARS

-

Material Grades

Defines fiber length, fineness, alignment, moisture windows, and structural/composite grade classifications.

-

Quality Benchmarks

Uniformity scoring, contamination limits, dust tolerances, binder adhesion profiles, and batch variance controls.

-

FEOC Procurement Standards

Aligned with IRA 45X/48C, CHIPS Act domestic content, USDA bioindustrial specs, and state manufacturing incentives.

-

Chain-of-Custody Verification

Tracks every batch from

field → hub → processor → manufacturer with moisture history, contamination notes, and carbon accounting. -

Industrial Qualification Pathways

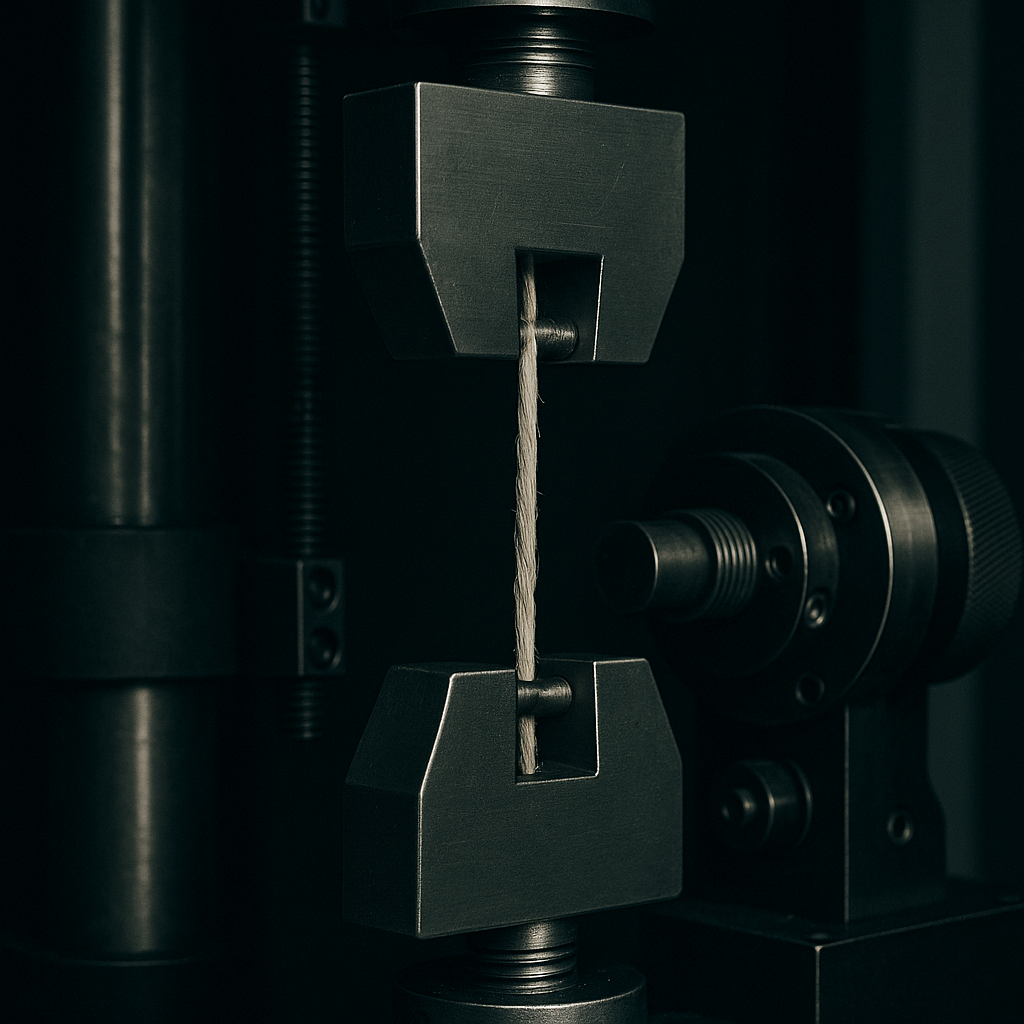

Outlines the testing, certification, and performance thresholds required to enter the national fiber supply chain.

WHAT WE STANDARDIZE

THE 7 ENGINEERING STANDARD CATEGORIES

-

Fiber Specifications (Hemp & Bamboo)

Defines length, fineness, bast/core ratio, moisture limits, retting quality, and composite/structural-grade thresholds.

-

Equipment Standards

Decorticators, crushers/chippers, magnetic separation, fiber cleaners, pelletizers, 3D printing feedstock processors — all with throughput, tuning, and performance benchmarks.

-

Composite & Polymer Compatibility

PLA, PHA, TPU, PP replacements, injection molding profiles, and 3D print pellet/filament performance windows.

-

Construction & Structural Standards

Hemp CLT, bamboo structural members, acoustic panels, exterior boards, moisture behavior, fire testing, and IBC code pathways.

-

Agricultural & Harvesting Standards

Planting density, harvest timing, retting methods, moisture control, baling requirements, and compliant transport guidelines.

-

Carbon & Biochar Standards

Soil carbon accounting, pyrolysis specs, biochar quality grades, long-term sequestration curves, and carbon credit eligibility.

-

Logistics & Trade Standards

Palletization, humidity thresholds, batch labeling, cross-border compliance, FEOC verification, and chain-of-custody requirements.

A real bioindustry only works when every part of the supply chain speaks the same engineering language.

These seven categories form that shared backbone.

Insurance Starts With Standards

This is how hemp and bamboo become “bankable.”

Standards turn uncertainty into measurable risk.

Measurable risk is insurable.

Insurable products become mainstream.

DBX defines:

failure modes

tolerances

lifespan bands

load-bearing curves

microbial & moisture limits

→ Insurers can price risk

→ Manufacturers can issue warranties

→ Municipalities can approve materials

→ Builders can spec fiber into real projects

THE 5 DBX CORE PILLARS

-

Manufacturers

Tune equipment, guarantee outputs, reduce failure rates.

-

Farmers

Deliver fiber that consistently meets industrial thresholds.

-

Universities & Labs

Feed verified research directly into DBX certification.

-

Municipalities

Use standards for permitting and code compliance.

-

Investors

Understand repeatability, risk, and scale potential.

Oil didn’t win because it was cheap.

It won because it was standardized.

We are giving hemp and bamboo the same industrial backbone,

only domestic, modern, and regenerative.